Fitting

the MZ-B 12Volt alternator to R67/2 and R51/3 models (and early R60’s? etc)

By

Stephen Henry

Owners

of the R67/2 and R51/3 wanting to replace their 6 volt charging system, but

retain the existing magneto, will face an additional challenge to owners of

later model bikes in fitting the MZ-B alternator.

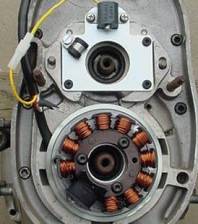

Unlike the photo Fig 1. below of an R69S timing case, borrowed from Duane’s web site, the earlier timing case does not have conveniently located

ventilation channels to run the cable for the alternator. If the cable is run

through the gap, between the alternator and magneto you will be unable to refit

the original magneto without making some modification.

Fig 1.

Fig 1.

Option

1. It may be possible to cut the outer insulation off the alternator cable to

feed the wires through the gap but the thought of fraying the inner wire

insulation, on all those sharp edges, and having a short circuit to earth is not

an attractive solution.

Option

2. Cutting a segment completely out of the MZ-B supplied alternator mounting

ring may allow you to feed the alternator cable through. One day I will remember/see why I did not solve the issue

this way.

Option

3. My approach was to remove some material from the alternator mounting ring

(Fig 2. shows the back of the mounting ring supplied by MZ-B) and a small

portion of the timing cover casting from the area circled area in the photo of

the timing cover, refer Fig 3.

Fig

2.

Fig

2.

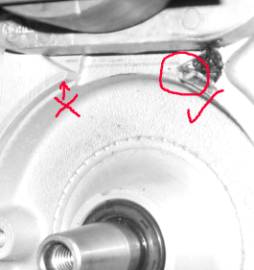

Fig

3.

Fig

3.

When

working out where to remove material from the timing cover I had the advantage

of having it off the bike so was able to see where the casting was thickest.

Fig 4. shows what the case looks like after competing the grinding of the

timing cover casting. I would

strongly recommend that you do not attempt to grind a channel in an equivalent

position to the ventilation channels shown in Fig1.

Fig 4.

Fig 4.

Fig

5. shows the alternator cable exiting between the MZ-B alternator and the

original magneto after grinding a channel in the casing and the alternator

backing plate

Fig

5.

Fig

5.

To

remove material from the alternator backing plate a round file was employed.

Fig 6.

Fig 6.

Fig 6.

Comments

- Would

I fit a MZ-B alternator to another bike? Yup.

- Owners

replacing both the existing magneto and charging system with MZ-B

replacement parts may not have to modify the timing case to get it all to

fit. They may however have to grind off some material where the wiring and

new coil ignition leads enter the top casing.

- For

people replacing the magneto ignition - The MZ-B website states there is

insufficient space to hide the MZ-B ignition coils in the petrol tank cavity

for R51 and R67 models. The coils will have to be attached elsewhere, unless

you are really creative the bike is going to end up looking “non

standard”.

- I

have fitted the voltage regulator in the frame where it is hidden by the

tank and right out of the way, refer Fig 6.

Time will tell if there is excessive heat build up and subsequent

regulator failure due to insufficient airflow in that location.

- It

seems to be possible to grind the timing case while it is in situ on the

bike, I would recommend removing the magneto and alternator first.

Fig

6.

Fig

6.

Stating

the obvious

1.

If you do not feel comfortable with

modifying the timing case casting on your bike, do not do it.

2.

Wear

safety glasses when grinding

the timing case casting

3.

Keep

the removal of material from the casting to a minimum, refit the alternator and

magneto frequently to see if the alternator cable feeds through the gap

4.

Mask off area’s on the bike where

you do not want aluminum

(proper spelling, aluminium) flakes ending up when grinding the timing case. It is

amazing how the aluminum flakes fly around.