Grease all electrical connections

This applies to all models of BMW motorcycles

In my work as an inspector of cell tower construction for AT&T, we deal with large power supplies and batteries. The huge battery bank can easily supply thousands of amps of current. That is 10 times that of an electric welder. A tool that accidentally crosses it can just about vaporize. It is not dangerous as far as getting shocked, as it is only 24 volts, but the danger is from getting burned.

The copper cables (wires) that connect them are as thick as your finger. It takes special procedures and tools to attach the terminals to the wire and then bolt them safely down. We grease everything. The grease gets pressed out of between the connections and forms an airtight seal. Air contains enough moisture to cause corrosion. Grease prevents corrosion, which would increase the resistance. Resistance will reduce current flow and could even become a diode that can generate radio interference. As an inspector, I require seeing a bead of grease squeezed out around the connections to prove that grease was used.

These are properly greased terminals in a cellular telephone (radio station) site. The key is for size reference. See the bead of light brown grease that has squeezed out and around the terminals? If you look closely, you can also see the upper part of the terminal where the black cable goes into the terminal. Look just below the crimp, and you can see a “window” or hole in the terminal. You can see some grease squeezed out through the hole. That is for me, the inspector, to be able to determine that the cable was fully greased before the terminal was crimped. All copper wire should be greased before the terminal is crimped. As a former BMW mechanic, starting with the /5 series, no grease was used when crimping the battery cable terminals. We often saw troubles only a year after the sale. No grease was used where the terminal was bolted to the battery.

How do we use this knowledge on our BMW motorcycle batteries?

This is evidence of what the “big boys” do to protect electrical connections that carry large amounts of current. Using this practice on all of your lead-acid batteries can only help you.

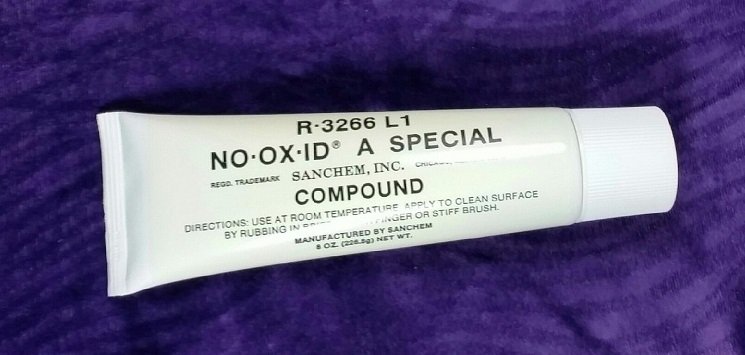

This is the grease used in cell tower construction. What is special about this grease is that it contains no additives of any kind. It is pure grease. Additives may have a chemical reaction with the components of the connection. They are often dissimilar metals. We call it NO-OX. Use it liberally on every electrical terminal crimp and connection.

We used the above tube because it made out job easier. A cell tower has two AC units of 5 hp each to keep the equipment cool. That cool air makes it difficult to squeeze the grease out of the tube. We open the tube, put it on the floor, and squeeze it out with our foot. This leaves us hands-free, and that was very important. Sometimes we used a toothbrush to spread it out.

This is one of the smaller containers that are available on Amazon, and they contain enough grease to last your lifetime with motorcycles.

If you don’t have the “NO-OX” grease, then use Vasoline. Regular wheel-bearing grease isn’t ideal, but far better than nothing at all.

We have all seen this under the hood of a car. It is caused by some of the battery electrolyte leaking at the battery post. Grease won’t prevent the leak, but it may prevent the same corrosion from deteriorating the connections. The molded battery cable terminals are the best ones, but sometimes we are stuck with using a “universal” cable connector. If it is the crimp type, then it is best if you solder it rather than crimp it. If soldering isn’t an option, then use grease liberally on the wire before crimping. At that point, it is best if you further protect the terminal by using some shrink tubing on the connection to help keep any acid or water out.

Use a small spot of grease on the connector of any item with a battery, even a dry cell type. How many times have you opened up a flashlight or other battery-operated device and found a leaky battery? Usually, it erodes the terminal and can even eat it up. The grease won’t prevent a battery from leaking, but it will save the metal terminal.

The coil connections need to have grease under those push-on connectors too. They cause a lot of trouble. If all of the push-on connectors had grease under them from the factory, you wouldn’t be having trouble now.

A new product is now available from the WD-40 folks.

The “WD” stands for water dispersant. The standard WD-40 that we have all used forever isn’t a lubricant. This new product is the answer. It is called Water Resistant Silicone Lubricant. Buy a can and use it for nearly everything that gets stuck or corroded.

Click to see what it looks like.

Another great use of this new product is with your standard wall outlets. Remove a device wire that is plugged into the outlet. Squirt a bit into each of the 3 connection holes. Plug the device wire in, and you will probably feel a huge difference. You will probably treat every outlet in your house.

Watch this excellent video on the product.

We all need to remove stuck fasteners. Here is a product that works, according to my dear friend, who is the top body man at a Ford dealership.

PB B’laster penetrating oil. It is widely available at AutoZone, Walmart, etc.

Updated 15 July 2022