/5 ignition for BMW motorcycles

I suggest converting to an electronic ignition system for excellent reliability and less maintenance. A few were available in the day, but Dyna III proved to be good. One can find a Dyna III for $300. A feature is that the old points system can be installed again in case that the Dyna III fails.

This page is about the battery coil ignition systems used on the /5, /6 and /7 BMW motorcycles. The official name is Kettering ignition. The points on this series of BMW motorcycles are part of an old ignition system called “points and condenser” or “battery/coil ignition.” The /5 was the first modern twin-cylinder BMW motorcycle to get battery coil ignition.

The basic /5 ignition system has only 4 parts.

1. The coil or coils are just a particular type of transformer. It steps the 12 volts DC up to about 30-40,000 volts.

2. The points are nothing but a switch. The wall switch to turn on lights is almost the same item. The main difference is that points open and close at a very high speed and are operated by a rotating part called a cam.

3. The condenser (or capacitor) is a storage device that protects the life of the points by reducing the arcing. (short explanation)

4. The spark plug provides a place for the high voltage to go by sparking across the gap to ground. This spark ignites the fuel.

My background is radio frequency electronics, so motorcycle electonics is at the kindergarten level. So, I won’t go deeply into the electronics of the values of inductance and capacitance that make it work.

It is a simple series tuned resonant circuit. The combination of the coil and condenser serves to generate the spark when the points (switch) are opened. If one, or both, of the (electronic) values, are off, then the points will experience a larger spark and will overheat and die prematurely. For our purposes, we want the points to experience as little arcing as possible through the rpm range. Points that arc wildly at either the high or low end of the rpm range won’t last long. Like so much in life, it is a compromise.

The basic circuit of battery coil ignition

These four parts are all that is needed to generate a spark for your BMW motorcycle. You can wire up these four items on your workbench and provide 12 volts to it, open the points, and the plug will spark. Make sure that the plug is grounded back to the coil case. On BMW motorcycles, lots of extraneous parts are in the circuit. The BMW motorcycle ignition switch, kill switch, and lots of other things may be wired in for control and safety, but they aren’t needed to make the ignition system spark.

Our old cars that used this system also had a distributor to direct the spark to the right cylinder. On a two-cylinder BMW motorcycle, we don’t have a distributor. We have two coils and both plugs spark at the same time. This produces what is called a “waste” spark. When the plug that isn’t on the compression stroke fires, nothing bad happens. It is just wasted. Each spark plug fires twice as often as needed during its life in a BMW motorcycle. This system is for simplicity, and it hurts nothing. This fact must be understood in the tuning process because the timing light will show both sparks.

Educate yourself with your perfectly running motorcycle.

I know (or hope) that your BMW motorcycle is working correctly, and this is a good time to practice for the time that it doesn’t run due to loss of ignition. In your dark garage, take a look at your points arcing while you rev it up and see what normal arcing is. When you later have trouble, this knowledge of what is “normal” could save you a lot of time.

Get used to seeing this arcing during every BMW motorcycle tune-up. It will change slightly in different parts of the rpm range. It is normal to see more sparking at each end of the rpm range. When it shows a change, you will recognize it instantly. The problem can be related to the coil, but it is usually easier and cheaper to change the condenser first. Look at the coils last.

The 12 volts that powers the BMW motorcycle ignition system arrives from the headlight switch via the wiring loom. I am operating from memory, but I think that wire is blue/green and it goes to a terminal on a coil marked 15. That same coil has another (minus or negative) terminal marked # 1. You will see a short wire there, and it is a jumper over to the other coil to a terminal marked # 15. That second coil also has a terminal marked # 1. The wire there should be black. It goes to the points.

Pull the black wire off of the # 1 terminal on the coil. This is not the # 1 that is the very short jumper wire to the other coil. Now you have no “switch” to open and trigger the spark. Remove both spark plug wires from the plugs and attached your spare set of plugs. They serve as the indicator for this simple test. You want to remove both so that you don’t accidentally fire the one still in a cylinder and “fire” it. Your spare set of plugs are hooked up to the spark plug wires and laying on the head to show when you get a spark. Now, turn the ignition on at the headlight. Use a spare wire or any way of shorting out that # 1 terminal to ground (earth for the Brits). Don’t keep it shorted out for a long time, as one second is more than enough time. When you remove the “short,” the spark plugs should spark. You can see and hear it. Since you don’t have a condenser in the circuit, the spark won’t be nice for running, but it will prove these three things.

1. That you have power to the ignition system, and this proves that the battery is good enough to operate the ignition system for this test. That is a simple requirement because the electric starter is 20 times harder, and the battery may not be that good.

2. That the coils are at least working minimally.

3. That your spark plug and wires are working.

The plugs are in the open air. That is atmospheric pressure. The plugs may fire in open “air” but not under compression. If the plugs fail to fire in the environment of air, then they won’t fire under compression. The color of the spark that you see is significant. If you see a red/yellow spark at this time, it may not fire under compression. If it is blue/purple, then you have a good spark. Put it all back together and check to see that you still have a working motorcycle.

Testing a failure of your ignition system

I divide up the ignition testing into three separate parts.

1. Power must get to the coils. The power could fail to get there because there isn’t any power due to a dead battery or poor connections. The kill switch (on some models) could fail and kill it all of the time. Any of the many wires leading to the ignition system could fail.

2. Power must get through the two coils. If the primary winding of either coil fails, then no power will get through. If the short jumper wire fails to make contact, then power fails to get through.

3. Power must be “switched” on and off after the coils. That is the function of the points.

Here are the steps to see which of the three have the failure. I don’t perform them in the order of likelihood but in the order of simplicity. Your battery must be able to run the headlights to be able to have enough current to operate the ignition system. If you doubt your battery, then use another source of 12 volts. You may “jump” from a car battery to your BMW motorcycle safely. When I say “safe,” I mean the electrics of both the car and bike. There is no chance of electrocution.

1. My first test is to hook up a plug to one of the spark plug wires. With the power on, lay it on the head and crank or turn the engine over. It should show a spark at the plug. This test only tells you if the system is completely dead. A healthy spark is blue/purple. A red/yellow spark is a weak one and may not allow the engine to run correctly, or at all. If you find no spark or weak spark, proceed with testing.

2. I would remove the front engine cover only after disconnecting the battery ground wire. I would rotate the engine until the points are closed. Reattach the battery ground wire for this test. With the ignition switch “ON” I would use my finger to lift the points open. You should see a spark at the test plug(s). If not, proceed.

3. I would suspect that the points aren’t making contact, and I would then test it. Rotate the engine until the points are open. Have the ignition power on. Use a screwdriver to short them across. Look for a spark at the plug when the “shorting” screwdriver is removed. That is simulating the opening of the points. If you now get a spark, then replace the points. Still, no spark, proceed.

4. The /5 and /6 are slightly different. Today is Sept 2, 2019, Labor Day. I have three /6 engines to examine, but no /5 for photos and info. I will proceed after I get the info that I need. A reader named Roy brought this to my attention, thanks.

5. Remove the fuel tank and make a continuity test of the primary side of each coil. With the ignition switch off and the points open, touch the ohmmeter leads to # 1 and # 15 of the coil, repeat on the other coil. That will show a completely open coil, replace them. The correct amount of resistance is less than 5 ohms. One coil could be “open” or infinite resistance, and the other is still OK. Replace them both, as they are the same age. It is reasonable for the coils to last 10-15 years or so. They are now about 30 years old, and that is unreasonable to expect them to be still OK. Replace them as a matter of course. Coils can partially function and be very hard to diagnose. To be safe, you should replace your unknown aged coils that seem perfectly good, but keep the old ones as spares. Coils can be found for around $50-$60, for both, on the Internet. They are standard 6 volt Volkswagen coils and easy to find.

If the tests, explained above, fail to show a spark at the plugs, maybe it has no power getting to the ignition system. Rotate the engine until the points are open. Hook up a “jumper wire” from the positive terminal of the battery to the # 15 terminal of the coil. Short the # 1 terminal of the other coil to ground. This test simulates the points. When you remove this “short” from the ground, you should be able to observe a spark at the plug(s). At this point, you have supplied power directly to the coils and eliminated the points and condenser too. You are testing only the coils. If it fails this test, check the small jumper wire to make sure it is making good electrical contact. If you can’t get a spark under these “friendly” conditions, then replace the coils. If it passes this test, you may still have intermittent coil problems that appear with heat and with the plugs under compression.

The two coil wiring diagram used on BMW motorcycles

One could wire up the coils in other ways, and the bike may run quite well. This is just showing the original wiring for optimum performance.

Setting the points

Setting the points gap on BMW motorcycles is easy, but is often misunderstood. The points available in the 70-80s would last for 20-25 K miles and often far more. I have heard that today’s points don’t last very long, but I don’t know the truth of that assertion.

To get the points to last, they must cool. To cool, they must open up widely (gap) for air to cool them. To get the engine to a high rpm, we need for the points to only open a little bit, or we risk something called “floating.” That is they won’t move back and forth fast enough to reach a high rpm. We are caught in a compromise between cooling (large gap) and high rpm (small gap). They could be anywhere from 012″ to .020″ and work very well. Average riding would never reveal the difference. BMW has settled on a .016″ (.4 mm) gap as the standard for their motorcycles. That way, we all set them at the same gap.

Cam lobes open the points on the advance mechanism. The lobes hit the fiber block on the points arm. As the miles go by, the fiber block wears away gradually. As it wears away, the points open to a smaller gap, and the timing changes. A smaller gap gives us retarded timing. We only need to set the gap back to the starting point (.016″), and the timing will be correct again. It is that simple.

This is the hard part to grasp

The adjustment for the points gap and the one for timing are different on BMW motorcycles. The points can be set at any gap, and the timing adjusted to work by rotating the plate (except on the R68 and R69), but the life may be shorter, or the rpm is limited, as mentioned above. On the other hand, if the timing adjustment (points plate) is constant, and the gap is changed, then the timing also changes. The world standard is that we accept one gap setting (in this case, .016″) and only contend with the timing plate adjustment. One doesn’t prefer to adjust the ignition timing by adjusting the gap, but only by rotating the plate. With normal wear, one may correct bad timing by setting the gap back to the correct amount, but that’s different than the initial timing of the ignition system.

Some owners find that the points plate is rotated to one end of adjustment, and still, the timing is off. Try setting the point gap a bit smaller or larger to compensate. If you are still within .012″ and .020″ it will still work correctly. You may need to remove the points plate and widen the oval holes a bit so that it can rotate more. I have only heard about this recently, so something has changed in the points provided today. Don’t obsess over this; do what it takes to get the timing correct. Make a note in your BMW motorcycle logbook.

Setting the points on any vehicle is often done incorrectly by professional and shade tree mechanics alike. Changing the gap does not make a “hotter, or cooler” spark at the plug(s).

How to gap the points

This drawing shows the way the feeler gauge (yellow) should be used at the points (orange). Look closely at the surfaces of the points, and you may see that they are slightly curved. I am not an artist, so imagine this. The gauge only goes in a tiny bit of the way. To go further will risk several things.

Don’t file the points

Some metal will migrate from one side of the points to the other. A small “tit” will build up on one side and a matching “valley” on the other side. Very little metal is lost into the atmosphere, mostly it just moves from one surface to the other. This irregularity disturbs many, but it is harmless. A point on one side of the points will still be .016″ from the matching spot on the other side of the points. If the “corrosion,” or tit, is filed off, then we have a “valley” and no matching “tit.” The “filed off metal” may lodge in the valley, only to come out later on and insulate the points. I have seen this happen several times. The engine won’t run. Don’t file points. Filing the points may satisfy your obsessive nature to make things look clean. It does make it easier to insert the feeler gauge, but now you know that you don’t need it inserted fully.

The feeler gauge may have a bit of oil on it, and that may insulate the points. Then the engine may not even run. To put the feeler gauge in farther than the edge only risks contamination. Don’t worry about the slight error due to the curved surface, remember that we only need to make the gap the same every time and all is OK. As long as we repeat our procedure, the result will be constant.

Behind the advance mechanism is the screw for setting the gap. When the lobe on the cam opens up the points, then the advance mechanism is in the way. The points are very hard to get to and people complain, but there is an easier way. Remove the advance unit and install this simple BMW motorcycle points tool. When replacing the advance unit, do not tighten that 10 mm nut very much. One gentle finger pull is enough. You may strip off the threads or break the end off of the cam. You will not be happy.

BMW motorcycle points tool from Paul Tavenier

The precision machined tube automatically opens the points the correct amount, no matter where the engine is turned. The attached “feeler” gauge is the correct one for the gap. A nice touch is that it is metric. It is not important, but very cool of Paul. Now the BMW motorcycle mechanical advance mechanism is no longer in the way and setting the gap is easy. Setting the points is quick and accurate. A points tool can be obtained from Paul at repairhead@sbcglobal.net (new address) and is about the same as the one above. Send him your name and address. A points tool will arrive in the mail on the honor system. You inspect, use it and then send him the money. The last I heard it was $20. I have owned a points tool like this for 30 years and used it hundreds of times. The points tool has paid for itself many times over. We should be thankful that someone like Paul Tavenier, a BMW rider himself, will do small runs of things for a reasonable price. He tells me that he sells a few a month, so this isn’t his retirement job, he isn’t getting rich. Thank him.

He also makes a tool for fixing the cam after you broke the tip off of the end of the camshaft.

The condenser

The condenser is frequently misunderstood. It is part of a series tuned circuit (of very low “Q,” or sensitivity) and is in parallel with the points. It is in series with the coil. Another way to think of it is that the points do nothing more than short out the condenser when closed.

Condenser failure modes

The condenser can fail to perform in 4 basic ways: shorted, open, intermittent, or be the wrong value.

1. If a condenser has shorted out, it will be the same as if the points never open. You will get no spark.

2. If a condenser is open, the points will have a large spark across them, and they will wear very quickly. It will run very poorly with lots of misfiring and backfiring.

3. An intermittent condition is the hardest one to “find” and will usually fail with heat, but not always.

4. Condensers are manufactured with considerable variation in capacitance and are measured in farads. In our case, microfarads, or millionths of a farad.

Because the circuit is of low “Q” (sensitivity), the value can vary by 20% with no adverse effect. If one tunes many of the same bikes, as we did, one learns to spot an abnormal amount of spark across the points, as the bike goes thru the rpm range. We seldom saw this condition, as I remember.

Condensers are very reliable and should be considered to be as reliable as the crankshaft. The original condenser could easily last the life of the bike. It is crazy to replace it when changing the points. That reduces reliability, as condensers are most likely to fail in the first few hours. In our shop we very rarely replaced condensers. I could probably count on one hand, certainly two hands, the number of failed condensers I have seen on BMWs in my life. A few of those had just been installed. Maybe after 30 years, it would be a good idea to change it, but not every five years.

Why spend your money and time to reduce reliability? Carry a spare if it makes you feel more secure.

Condenser test for BMW motorcycles

It is common for a condenser to be intermittent and only fail under high temperatures.

If the condenser is shorted out, then it will show low resistance on an analog (old style) ohmmeter. Put the meter on the 10k or 100k test range. Put the leads across the condenser and watch the meter. The needle should drop down a bit and then begin to increase or move back towards a complete open. How far it drops and how fast it raises depends upon the quality of your meter. At least under those conditions and temperature, the condenser is good. Only if it shows a direct short, have you performed a real test. If it shows bad, then it is bad. If it shows good on this test, maybe it is good.

If you have a “miss” that you can demonstrate, or detect, while the engine is running in neutral, then you can do a sort of test on it. If your anomaly only occurs while riding at 100 mph on a cloudy day, then this one is useless. Remove the BMW engine front cover so that you can observe the points as it runs. Do this in your dark garage. Start your BMW motorcycle engine and run it up through the rpm range where it misses, misfires or has whatever symptom occurs. The arc (spark) across the points should stay minimal and only slightly change at the high or low end of the rpm range. If you see a big change in the arcing as it starts to miss, then you have just shown that you have an ignition problem. The condenser is highly suspect.

A dead or intermittent ignition system on a BMW motorcycle may also be caused by the throttle cables shorting out against the coil terminals up under the tank. Check the routing.

Just about any auto condenser will work to make your BMW run again. It need not even mount up to the original place on your BMW motorcycle. It can be mounted at the coils under the tank. Just cut the wire to the original condenser and attach the “new” one to the coil terminal that goes to the points.

Dwell for BMW motorcycles

A lot has been made of the dwell angle, and it can be very important to the proper operation of an internal combustion engine. The dwell angle is the number of degrees of rotation of the crankshaft or distributor during one cycle that the points are closed. The dwell became more important as engines had more cylinders and would attain higher rpm. For a distributor to provide a spark to 8 cylinders, its rotation is divided into 8 parts. Each is identical. The points are closed for a very short time. The more cylinders, the less time. The higher the rpm, the shorter the time. An engine with 8 or more, cylinders and operating at a high rpm will need to have the points closed a long time to get the “charge” built up in the coils. You may investigate this in great detail by inserting “ignition dwell” into Google.

Our bikes do operate at fairly high rpm, but with only two cylinders. The amount of time for the points to be closed up is four times greater than a V8. The BMW boxer just doesn’t have a need for more “time” to have the charge built up. The boxer engine has no use in the world to have the dwell measured. There is no damage or problem with measuring dwell, it is just that it is a waste of time. The dwell could be “off” by 50% and the system would work just fine. Mostly it is a waste of time to get the meter and attach it. I would compare this to using a measuring beaker to get a drink of water. It matters none of you have 790 ccs of water or 800 ccs of water in your glass when you can only manage to drink 300 ccs anyway. Don’t even think about dwell on your boxer unless you expect to operate it at about 20,000 rpm and above.

Points float

It is possible for points to “float” and not allow the engine to reach normal rpm in any gear. The first time I found this one, I was utterly stumped. It was on a /2, and I had tried everything. I even swapped out the magneto, and everything worked again. I was able to open the points with a long thin screwdriver and let them go. They didn’t snap back as I thought that they should. New points fixed it. I have since seen this failure a couple of more times. In each case, the engine would about reach full advance as observed by a timing light. That is only mid-range, and the rpm wouldn’t go higher. Each time I was able to see that the points didn’t snap back shut as they should.

Another failure that was very hard to troubleshoot was the engine reaching some rpm and then sputtering. It could happen in lower gears, or not.

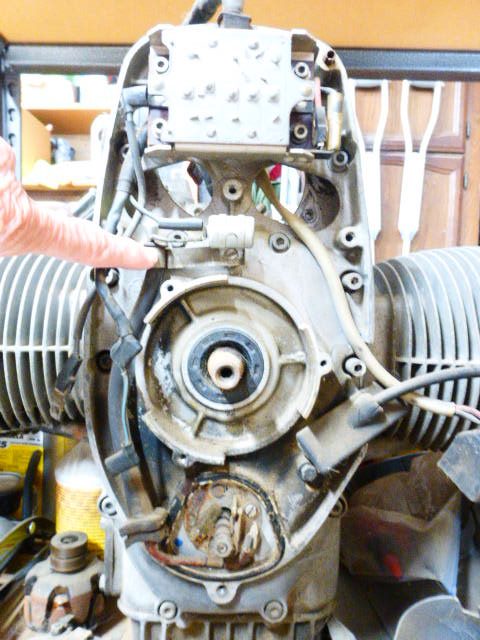

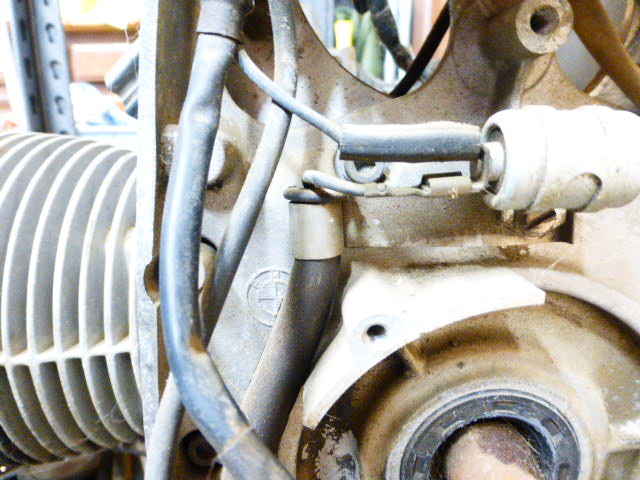

You can see my finger pointing to a metal strap that wraps around the rubber tube containing the wire that goes down to the points.

At the lower part of the engine is the points area. The points and cover have been removed. You can see the black rubber seal that is sort of oblong in shape. Replacing that seal is not simple. It is reported to be hard to find, and hard to install. Don’t bother with that original seal.

This simple fix is from the /5 United group years ago and was offered by Scott. That forum no longer exists.

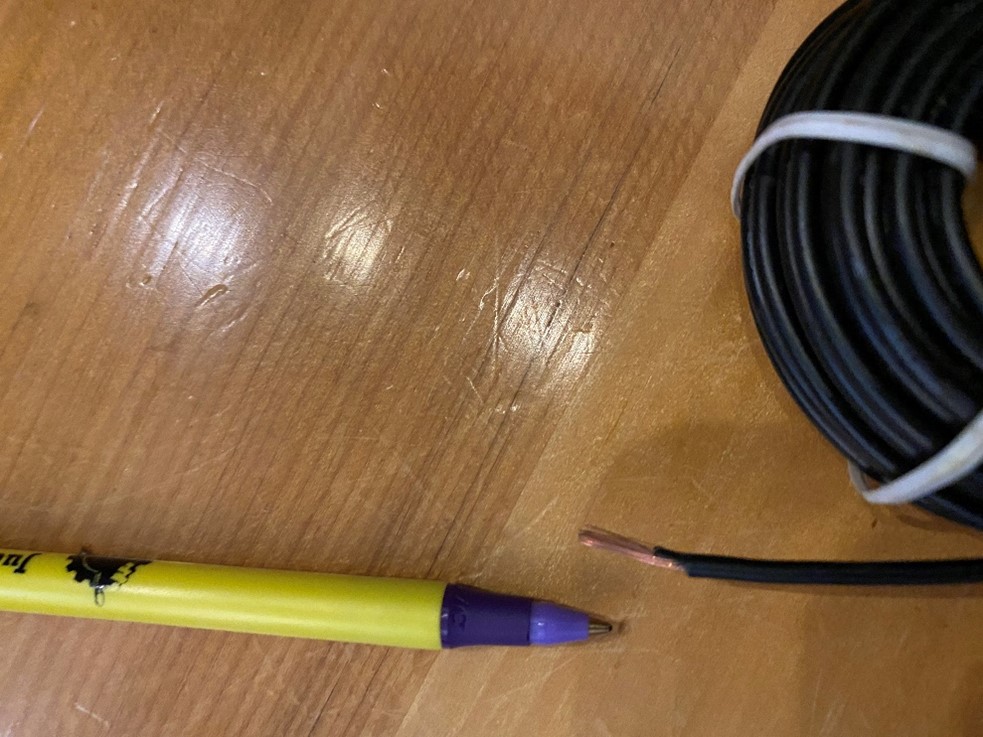

The fix is to throw away that rubber strip. Then you get a piece of copper wire with the insulation on it , cut it to length and you can actually mold it to the right shape.

I forget the gauge but I have a roll of it. The outside diameter of the insulation is .1 inch with the wire inside being one half that. It just needs to stick up out of the groove a little to make contact with the cover. It stays in place very nicely and is easy to replace when needed.

See the photo below of the wire that I use.

In the very center of the photo is the flat metal strap that holds the tube with the points wire. You must push that metal strap as far back as possible. Otherwise, it can vibrate at some rpm and touch the points wire, shorting it out. As soon as we learned about this failure, we would shove all of them back. By this late date, I would hope that none would need this fix.

Click here for /5 related information

Updated 24 Sept. 2020